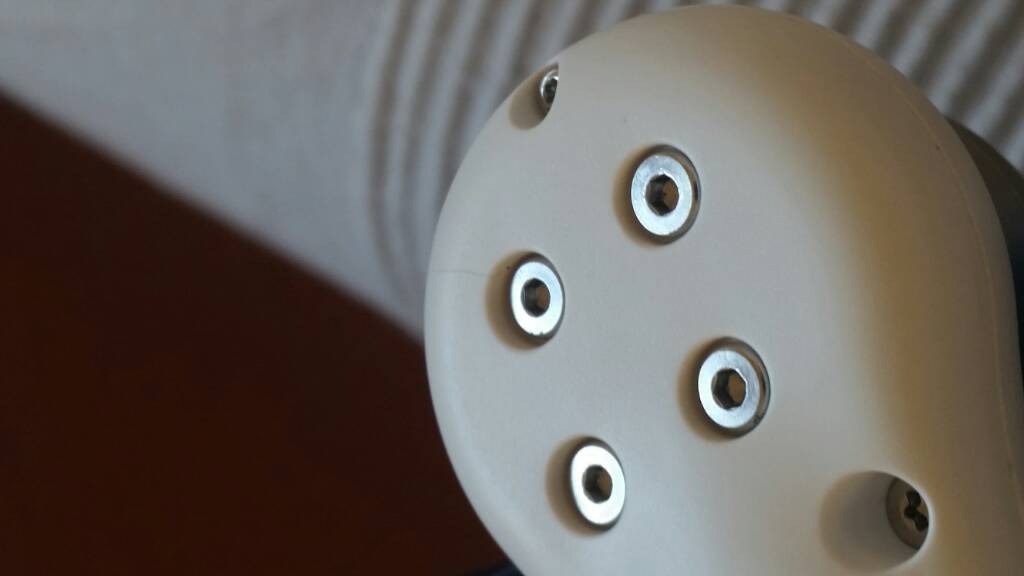

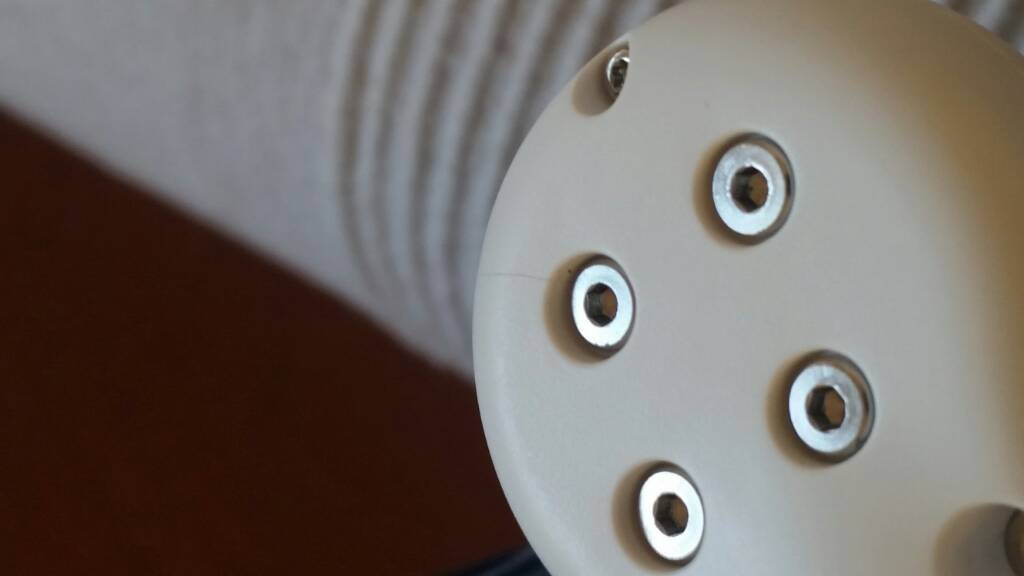

Hi everybody this is just to confirm that DJI phantom3 standard shell keeps craking under motors despite both top.and bottom shells were replaced just 1 month ago and only 2 flights...don't even know if it's worth trying to send it back again...

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

..new cracks after shell replacement

- Thread starter Ciccio

- Start date

Ok ...

Plast Aid is really a plastic solvent - ignore the comments that will initiate !! Its MEK basically - used by the Plastic Model people as a solvent glue to join their parts with minimum glue joint visible. It is same as Plast Weld.

I have used it - but as you see yourself - it is not a structural form of glue ... in fact it can weaken what it is applied to if not careful. I didn't actually advise to use Plast Aid ... that's down to others !

I prefer a glue or compound that ADDS to the structure such as PU Glue. It fills cracks / gaps etc. and is sandable. It adds strength for no weight.

Second is the use of the metal end plates to further strengthen the arms ends.

The Plastic used in such models is difficult to find a glue that actually holds well. Resins such as Epoxy do not hold as well as some think ... it soon starts to lift away from the plastic. Polyester Resin used in traditional fibreglass work will actually eat this plastic. Polyurethane is the only one that is tenacious enough to actually hold and stay holding.

I own model and full size boats ... you soon start to learn what glues you can use and not use !!

Nigel

Plast Aid is really a plastic solvent - ignore the comments that will initiate !! Its MEK basically - used by the Plastic Model people as a solvent glue to join their parts with minimum glue joint visible. It is same as Plast Weld.

I have used it - but as you see yourself - it is not a structural form of glue ... in fact it can weaken what it is applied to if not careful. I didn't actually advise to use Plast Aid ... that's down to others !

I prefer a glue or compound that ADDS to the structure such as PU Glue. It fills cracks / gaps etc. and is sandable. It adds strength for no weight.

Second is the use of the metal end plates to further strengthen the arms ends.

The Plastic used in such models is difficult to find a glue that actually holds well. Resins such as Epoxy do not hold as well as some think ... it soon starts to lift away from the plastic. Polyester Resin used in traditional fibreglass work will actually eat this plastic. Polyurethane is the only one that is tenacious enough to actually hold and stay holding.

I own model and full size boats ... you soon start to learn what glues you can use and not use !!

Nigel

S

sandman259

Guest

Ok ...

Plast Aid is really a plastic solvent - ignore the comments that will initiate !! Its MEK basically - used by the Plastic Model people as a solvent glue to join their parts with minimum glue joint visible. It is same as Plast Weld.

I have used it - but as you see yourself - it is not a structural form of glue ... in fact it can weaken what it is applied to if not careful. I didn't actually advise to use Plast Aid ... that's down to others !

I prefer a glue or compound that ADDS to the structure such as PU Glue. It fills cracks / gaps etc. and is sandable. It adds strength for no weight.

Second is the use of the metal end plates to further strengthen the arms ends.

The Plastic used in such models is difficult to find a glue that actually holds well. Resins such as Epoxy do not hold as well as some think ... it soon starts to lift away from the plastic. Polyester Resin used in traditional fibreglass work will actually eat this plastic. Polyurethane is the only one that is tenacious enough to actually hold and stay holding.

I own model and full size boats ... you soon start to learn what glues you can use and not use !!

Nigel

Plast-aid is not used or never made for the plastic model world for glue. It is nothing like plast weld. It was made for the hot tub world that is why it is sold at pool/spa places. Not sure why his cracked. Mine has been on over a year and still rock solid. I've actually never heard of anyone's ever cracking again after using it...

Seems that there must be two versions then .... it only takes a small change in label / name so I concede that one ...

MEK which is Plast Weld is sold over here as Plastic Weld Cement ...

I assume that OP must have used the solvent version of whatever name it has ... otherwise it doesn't make sense - I agree.

Nigel

MEK which is Plast Weld is sold over here as Plastic Weld Cement ...

I assume that OP must have used the solvent version of whatever name it has ... otherwise it doesn't make sense - I agree.

Nigel

S

sandman259

Guest

I would be curious to see what ciccio shell looks like from the inside. If the crack was all the way through the plast-aid as well or if the plast-aid is still intact, which is what I assume. That would mean it didn't adhere. If put on correctly on a clean oil free plastic surface it's almost impossible to remove without grinding it off...

S

sandman259

Guest

If the cracks are as usual around motor mount screws - there's no need to open up shell ... just remove motor screws, carefully prise the motors aside being careful not to strain the wires. You can then see the inside where motor sits.

Nigel

Nigel

I've replaced my shell 2 times due to cracks. The last time I carefully filled in the voids with epoxy making sure I didn't interfere with screw mounts and offset edge where the top and bottom meet. 5 months and about a dozen flights with one hard landing all is good.

Similar threads

- Replies

- 9

- Views

- 2K

- Replies

- 1

- Views

- 2K

- Replies

- 39

- Views

- 5K

- Replies

- 9

- Views

- 3K