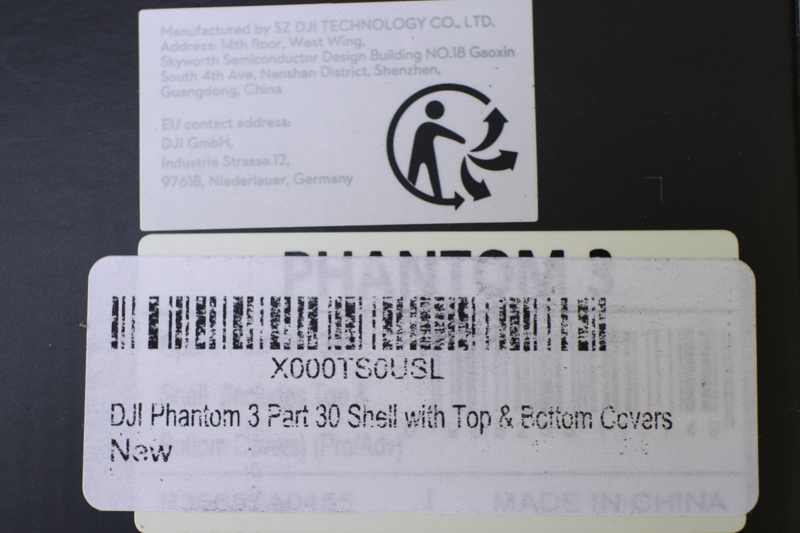

New shell from Amazon / Rotor Logic is complete crap. It's so flimsy I'm scared to start re-assembly. what a joke from DJI. It must weigh half of what the original one does. When you hold it up to the light it's twice as transparent as the original one. Is this my only option for a shell ?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

New P3 Pro body shell from Amazon / Rotor Logic is complete crap. Where can I get an original one?

- Thread starter Richard Gozinya

- Start date

msinger

Approved Vendor

- Joined

- Oct 30, 2014

- Messages

- 31,960

- Reaction score

- 10,786

- Location

- Harrisburg, PA (US)

- Website

- phantomhelp.com

You could try to track down the old version of the shell. However, it'll probably be tough to find and it seems to be more susceptible to cracking (hence the redesigned shell).

I never had ANY problems with mine cracking until it hit pavement from a dead drop of aprrox 100 feet. My original shell was fairly robust. The plastic in this NEW shell is so flimsy I'm scared to continue assembly. It literally pales in comparison to my original. There must be at least 3 versions of this shell if this is the NEWEST "improved" version. What a load of crap.You could try to track down the old version of the shell. However, it'll probably be tough to find and it seems to be more susceptible to cracking (hence the redesigned shell).

Last edited:

- Joined

- Oct 30, 2015

- Messages

- 325

- Reaction score

- 236

- Age

- 53

That's the original DJI shell. The exact same shell of your P3 - every P3 in fact - with perhaps only a few small modifications in the sub-motor design. But it's the same plastic, same design, same spec, same everything. It just feels more solid when everything is assembled, but it's just an impression. I've been dealing with these shells for a while and in all honesty never came across two very different ones in regards to the specs you mentioned.

- Joined

- Mar 14, 2016

- Messages

- 47

- Reaction score

- 3

- Age

- 71

Maybe so - but I replaced the top of the shell two weeks ago with the rotor logic shell. 5 flights since then and I have a crack by the motor on one of the arms. No crash, no hard landing - no nothing. I did take the screws out last night - did not notice the crack (the two screws on each arm that go into a metal fitting - to add blue lactite which I didn't have when I assembled it. I did not over torque any screw but here I am. I think I'll use some bondic on it for now.

- Joined

- Aug 26, 2016

- Messages

- 73

- Reaction score

- 21

- Age

- 72

LOCTITE® THREADLOCKER BLUE 242®

NUT AND BOLT LOCKER

Not Recommended For

NUT AND BOLT LOCKER

Not Recommended For

- Use on plastic parts, particularly thermoplastic materials where stress cracking of the plastic could result

- Joined

- Mar 14, 2016

- Messages

- 47

- Reaction score

- 3

- Age

- 71

LOCTITE® THREADLOCKER BLUE 242®

NUT AND BOLT LOCKER

Not Recommended For

- Use on plastic parts, particularly thermoplastic materials where stress cracking of the plastic could result

That is not a news flash - I am well aware - these screws go into metal fittings and if you look at them when you unscrew them you will find they had blue loctite on them.

- Joined

- Aug 26, 2016

- Messages

- 73

- Reaction score

- 21

- Age

- 72

Doesn't matter if they go into metal fittings. It's the oxidizers that permeate surrounding plastic. The cyanoacrylate used in the Loctite is stabilized by peroxide or some other type of chemical that forms free radicals. Once the surrounding oxygen in the air is absent (anaerobic), the metal ions react with the free radical producer giving the cyanoacrylates room to attach to each other and polymerize. This is how the adhesive bonds the two metal parts.

The free radicals would also attack nearby plastic material causing imbrittlement as the polymer chains are breaking down.

I was just trying to provide some friendly advice.

The free radicals would also attack nearby plastic material causing imbrittlement as the polymer chains are breaking down.

I was just trying to provide some friendly advice.

- Joined

- Mar 14, 2016

- Messages

- 47

- Reaction score

- 3

- Age

- 71

Yeah and I didn't meant to be snarky - sorry. But do you think it could have had caused a crack within just 12 or 14 hours?

Thanks

Thanks

- Joined

- Aug 26, 2016

- Messages

- 73

- Reaction score

- 21

- Age

- 72

Doesn't take long if you put a lot of the stuff on and it leaks all around and there is stress on the plastic.

YES. Sorry to say it breaks down the plastic in minutesYeah and I didn't meant to be snarky - sorry. But do you think it could have had caused a crack within just 12 or 14 hours?

Thanks

I have never had a screw fall out or come loss on a P3. Why people use locktight on there drone is beyond reason.YES. Sorry to say it breaks down the plastic in minutes

I have never had a screw fall out or come loss on a P3. Why people use locktight on there drone is beyond reason.

I've not had any screws come lose either.

However I do understand why people want to ensure their screws don't loosen off !

Until I inadvertently saw what Loctite can do to certain plastics I had no idea as to its destructive nature. Luckily it was a $10 Buggy part that I got some Loctite on and the area literally crumbed before my eyes!

There are products designed specifically for metal screws in plastic.

Before loctite, many gunsmiths used linseed oil. Beeswax is another option.

Sent from my iPad using PhantomPilots

Sent from my iPad using PhantomPilots

- Joined

- Mar 14, 2016

- Messages

- 47

- Reaction score

- 3

- Age

- 71

- Joined

- Aug 26, 2016

- Messages

- 73

- Reaction score

- 21

- Age

- 72

- Joined

- Oct 30, 2015

- Messages

- 325

- Reaction score

- 236

- Age

- 53

Maybe so - but I replaced the top of the shell two weeks ago with the rotor logic shell. 5 flights since then and I have a crack by the motor on one of the arms. No crash, no hard landing - no nothing. I did take the screws out last night - did not notice the crack (the two screws on each arm that go into a metal fitting - to add blue lactite which I didn't have when I assembled it. I did not over torque any screw but here I am. I think I'll use some bondic on it for now.

I'm not disputing the occurrence of cracks, I know it happens, it's been widely reported, documented and accepted. But the fact is that Rotor Logic only sells DJI original shells, there's no "Rotor Logic brand P3 shells" or any other P3-like shell made by third parties for that matter. Only DJI-made shells, so if any of those are cracking they're suffering the exact same problem as every other OEM DJI shell that has cracked, nothing new here. Even though some may crack (like OP and others), the specs are the same because they're made by DJI.

- Joined

- Mar 14, 2016

- Messages

- 47

- Reaction score

- 3

- Age

- 71

I'm not disputing the occurrence of cracks, I know it happens, it's been widely reported, documented and accepted. But the fact is that Rotor Logic only sells DJI original shells, there's no "Rotor Logic brand P3 shells" or any other P3-like shell made by third parties for that matter. Only DJI-made shells, so if any of those are cracking they're suffering the exact same problem as every other OEM DJI shell that has cracked, nothing new here. Even though some may crack (like OP and others), the specs are the same because they're made by DJI.

Didn't they though - at some point change the shells to have greater structural integrity? I'm wondering if they are working through a supply of the original shells.

msinger

Approved Vendor

- Joined

- Oct 30, 2014

- Messages

- 31,960

- Reaction score

- 10,786

- Location

- Harrisburg, PA (US)

- Website

- phantomhelp.com

Check out this thread to see photos of the changes they made.Didn't they though - at some point change the shells to have greater structural integrity?