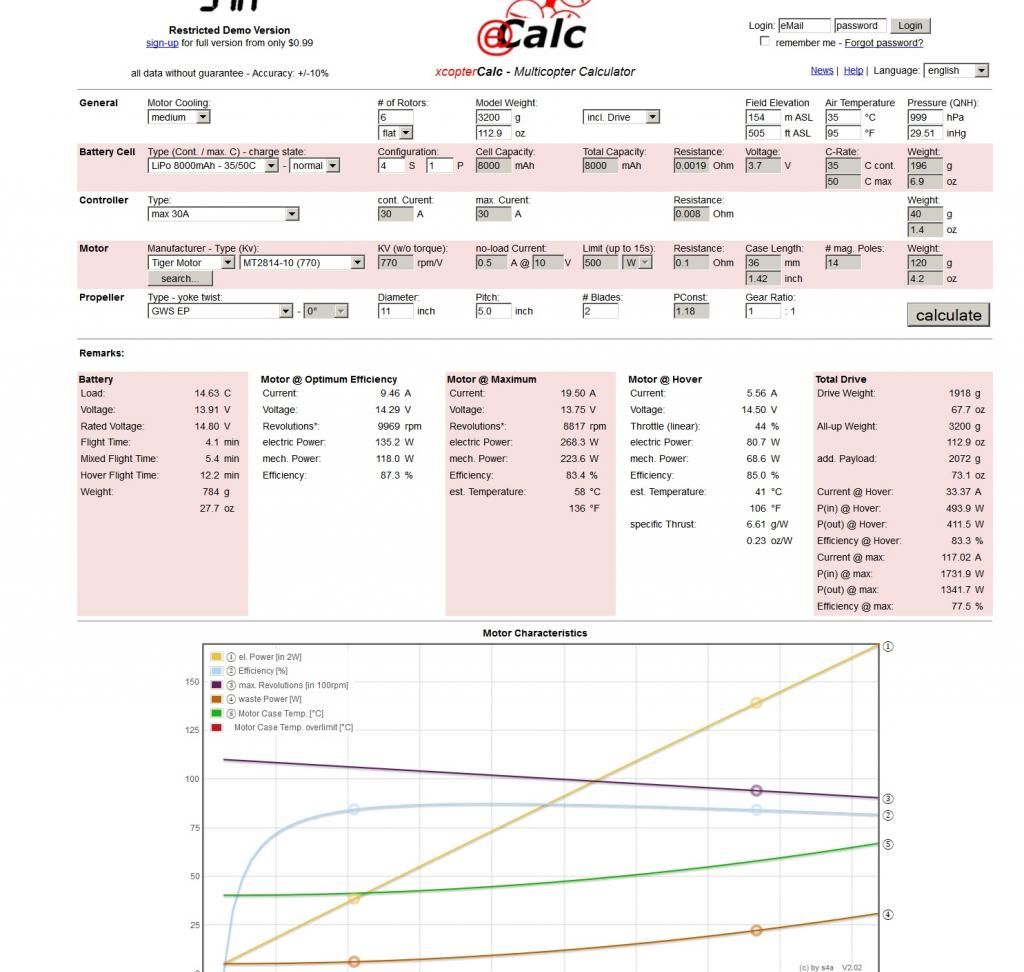

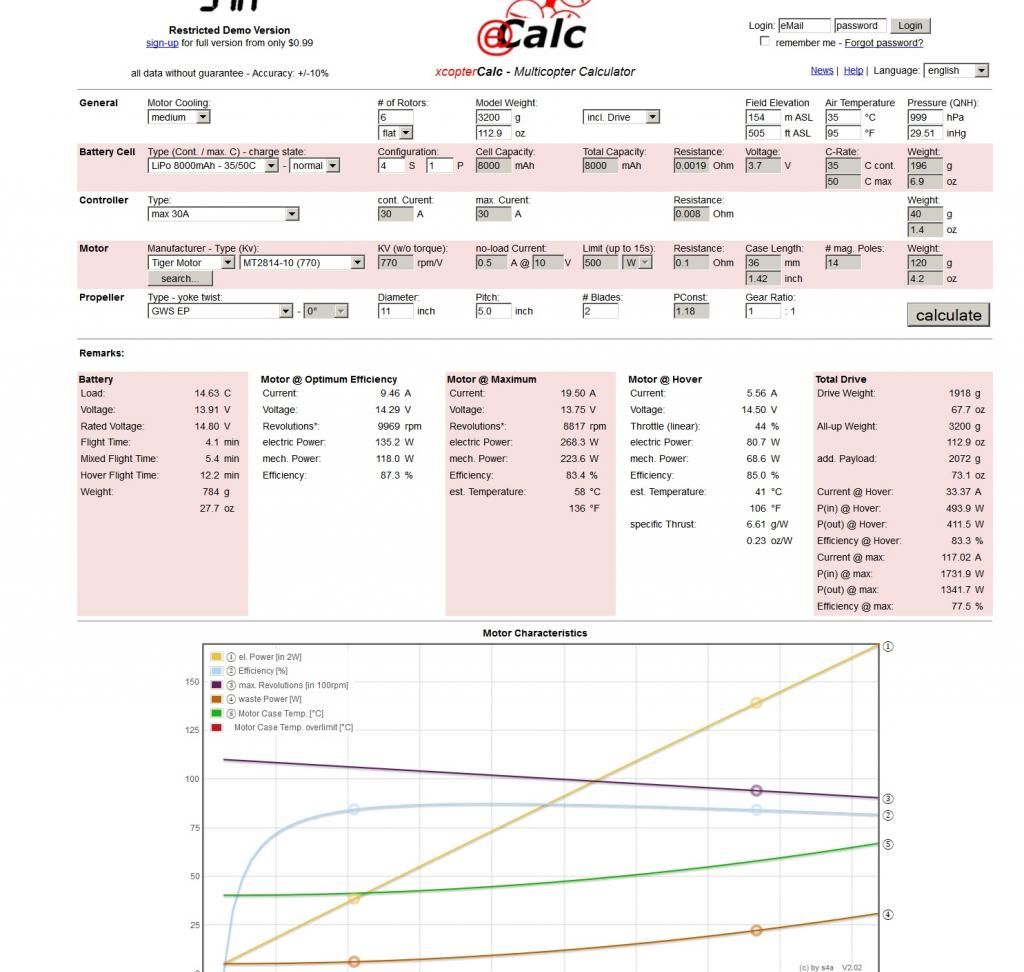

I've never used full throttle on anything I've flown. This will mostly be stuck in a high hover for live broadcasting. I think the linear throttle on E-calc said something in the low 40% range to hover, and in the 30% range with the 12" props.

I have a laser thermometer-so I'll be monitoring everything very closely. I have a little over 60 days to either crash/melt this, or sign it off as "safe" for the work I need it to do.

And-I think maybe someone is misreading the E-calc data.

tell me what you think;

I have a laser thermometer-so I'll be monitoring everything very closely. I have a little over 60 days to either crash/melt this, or sign it off as "safe" for the work I need it to do.

And-I think maybe someone is misreading the E-calc data.

tell me what you think;