Hey guys,

I built The Ultimate P3 Prop Balancer !!

I never liked the available prop balancers because there were too many variables.

The DuBro has 8 points of contact, way too much friction for my liking,

The Speedy Prop Balancer (see below) has to be perfectly level and it has two points of contact / friction.

I just don't like it.

So I decided to build The Ultimate Prop Balancer,

Here's how it's done;

#1...you'll need a M6 x 1.0 RH thread bolt,

#2...I search the world over and could not find a M6 x 1.0 LH thread bolt so I purchased a M6 x 1.0 LH thread all thread rod,

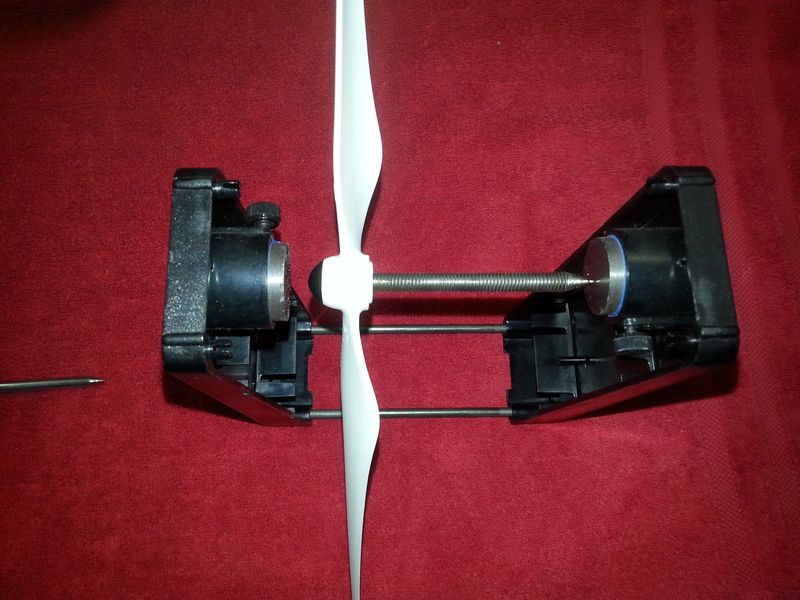

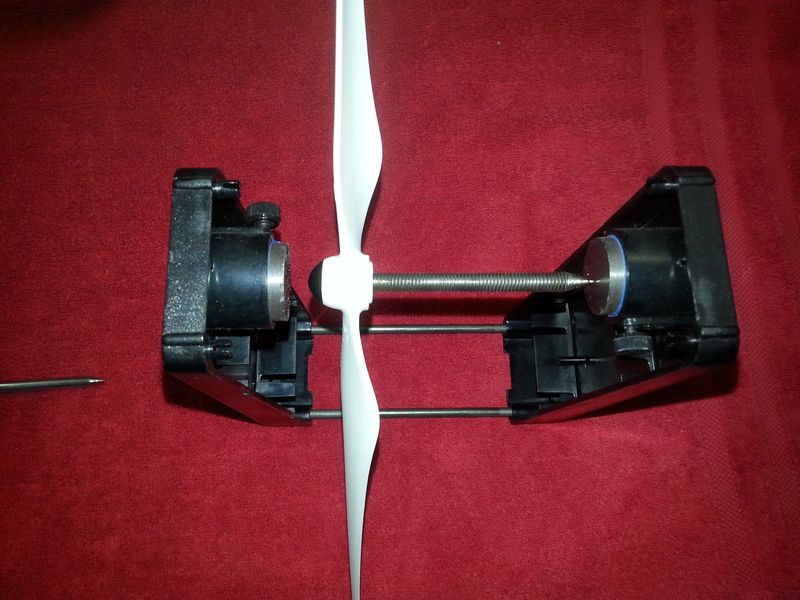

#3...you'll need a Top Flight prop balancer,

Cut the head off the bolt and cut an equal length peice of all thread,

These are the balance shafts.

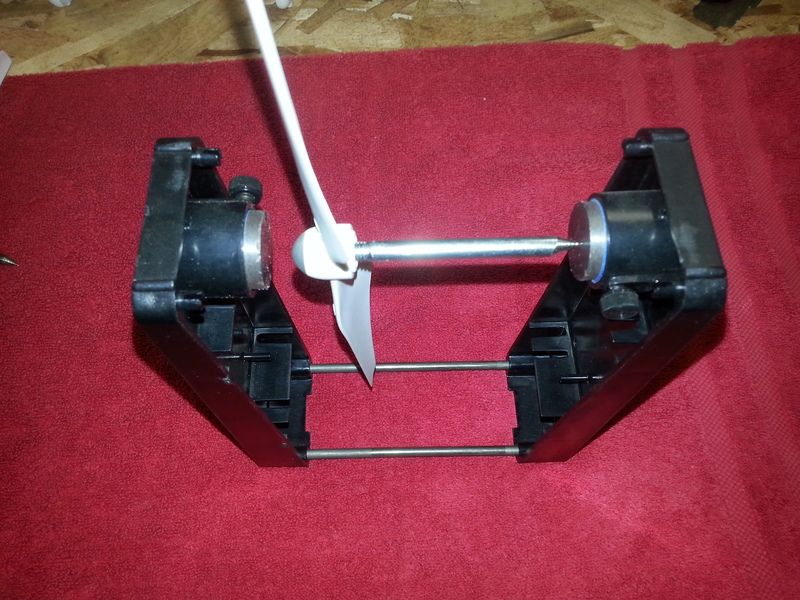

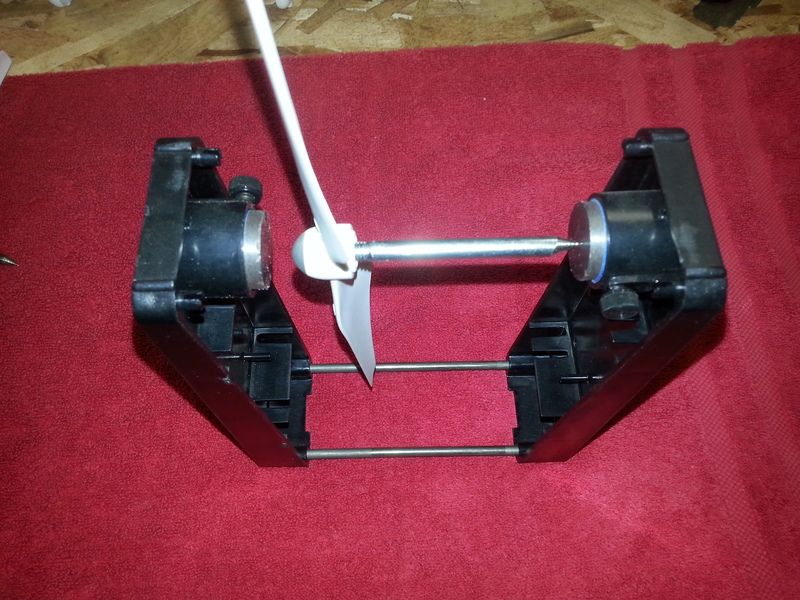

Grind the sharpest point you possibly can onto the opposite end of each balance shaft.

Mount one of the balance shafts onto the Top Flight Balancer,

The Top Flight Balancer has two metal rods that join the two upright pieces where the magnets are,

Measure the air gap, mine was 1.25",

Cut the metal rods .25" less than the air gap, I cut 1" off mine.

Assemble the Top Flight Balancer,

Screw a prop onto one of the balancing shafts,

Mount this assembly into the TopFlight Balancer,

!! NOTE THE AIR GAP !!

So, what you now have is The Ultimate Prop Balancer, there is only one single pin point of contact and it is a tiny needle point, it has the absolute least amount of friction possible.

One more thing, I used a torch and heated each one of the needle points till red hot, then I quenched them, this hardened that point, I then groomed each point till sharp....presto magic a hardened pin point with extremely low friction !!

This prop was perfectly balanced with the Speedy Prop Balancer, now look at it, one blade dropped to the bottom, no way was this prop balanced.

I built The Ultimate P3 Prop Balancer !!

I never liked the available prop balancers because there were too many variables.

The DuBro has 8 points of contact, way too much friction for my liking,

The Speedy Prop Balancer (see below) has to be perfectly level and it has two points of contact / friction.

I just don't like it.

So I decided to build The Ultimate Prop Balancer,

Here's how it's done;

#1...you'll need a M6 x 1.0 RH thread bolt,

#2...I search the world over and could not find a M6 x 1.0 LH thread bolt so I purchased a M6 x 1.0 LH thread all thread rod,

#3...you'll need a Top Flight prop balancer,

Cut the head off the bolt and cut an equal length peice of all thread,

These are the balance shafts.

Grind the sharpest point you possibly can onto the opposite end of each balance shaft.

Mount one of the balance shafts onto the Top Flight Balancer,

The Top Flight Balancer has two metal rods that join the two upright pieces where the magnets are,

Measure the air gap, mine was 1.25",

Cut the metal rods .25" less than the air gap, I cut 1" off mine.

Assemble the Top Flight Balancer,

Screw a prop onto one of the balancing shafts,

Mount this assembly into the TopFlight Balancer,

!! NOTE THE AIR GAP !!

So, what you now have is The Ultimate Prop Balancer, there is only one single pin point of contact and it is a tiny needle point, it has the absolute least amount of friction possible.

One more thing, I used a torch and heated each one of the needle points till red hot, then I quenched them, this hardened that point, I then groomed each point till sharp....presto magic a hardened pin point with extremely low friction !!

This prop was perfectly balanced with the Speedy Prop Balancer, now look at it, one blade dropped to the bottom, no way was this prop balanced.

Last edited: