- Joined

- Apr 30, 2013

- Messages

- 18

- Reaction score

- 0

Hey All,

Reamed / bored out my Graupner props to ~ 8mm today and just need to balance them before mounting on the Phantom. The only thing that has me scared is the lack of the motor shaft "key" which would prevent the prop from spinning freely on the shaft.

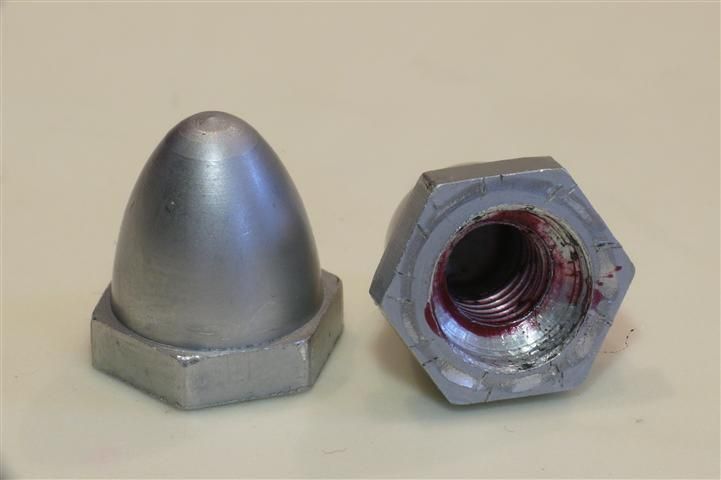

How are all of you Graupner owners tightening down the props? From searching, I gather you just use loctite on the shaft threads and I've come across people using washers underneath (?) the prop ... anyone find the need to use lock-washers on the top of the prop (i.e. between the prop and the nut)? Are you replacing the nut? I plan on just using the aluminum dome / castle nuts which came with the Phantom.

Thanks!

Paul

Reamed / bored out my Graupner props to ~ 8mm today and just need to balance them before mounting on the Phantom. The only thing that has me scared is the lack of the motor shaft "key" which would prevent the prop from spinning freely on the shaft.

How are all of you Graupner owners tightening down the props? From searching, I gather you just use loctite on the shaft threads and I've come across people using washers underneath (?) the prop ... anyone find the need to use lock-washers on the top of the prop (i.e. between the prop and the nut)? Are you replacing the nut? I plan on just using the aluminum dome / castle nuts which came with the Phantom.

Thanks!

Paul