- Joined

- Nov 28, 2013

- Messages

- 491

- Reaction score

- 2

Ok- so I can't hang with the big dogs... but I'll be damned if I will stay on the porch.

What is cooler than a well built and set up multi-rotor when it take off, hesitates for a sec, and then retracts it's landing gear up and out of the potential shot? For me, it is just wicked. (I know- small minds)

So I set out to see if it was possible, and actually feasible with the goal to not add too much weight to make it pointless... I think I pulled it off.. or up :roll:

Here are the 18 gram retracts found on ebay that are the foundation for the project: http://www.ebay.com/itm/121228846555

Be sure to add a y- cable as this will connect the gear into the Rx: http://www.ebay.com/itm/181180218953

You need to have an aftermarket radio and receiver- I use a Futaba and a FrSky TFR8SB (8 to 16 channels) with the landing gear hooked in on channel 8 and triggered by a single 2 way switch (H on my 10CAG) The Rx stated will bind to any FASST Futaba, and with standard config at your specs on the radio, you still do not loose X1 or the gimbal tilt. This is a whole other thread, so I will not go into detail on radio and receiver binding and programming- I am counting on you already understanding that part.

Next I liberated some parts from a set of CF landing gear that was removed due to too much weight- here is where the DIY in you will have to shine through- I would like to have dewey make a special mount, and then put it together but I doubt there would be enough demand- but based on what I have done here, he could make a few measurements and put something together rather easily if he, or someone else with a 3d printer was motivated. It would reduce the weight by half I believe from my mock up.

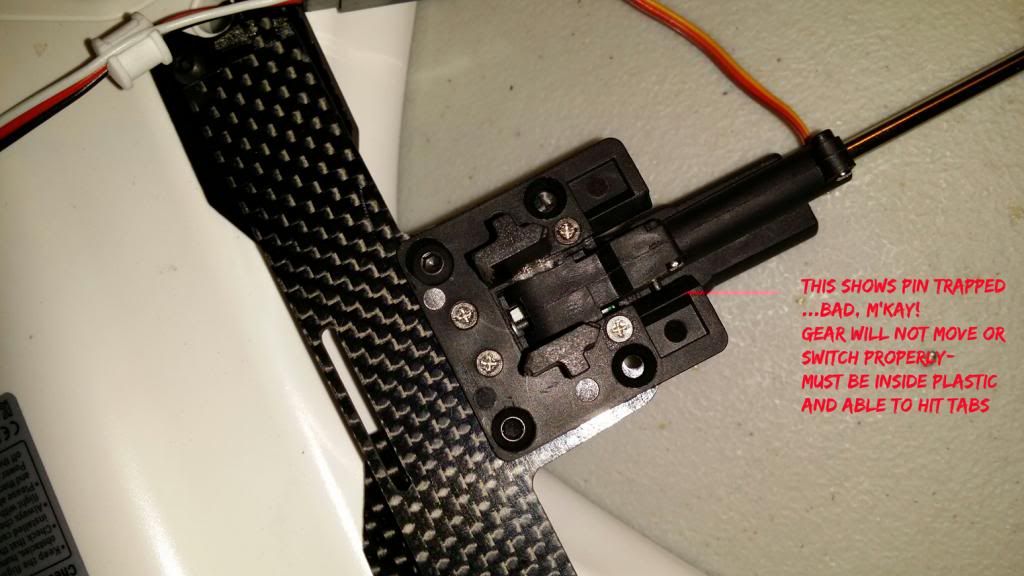

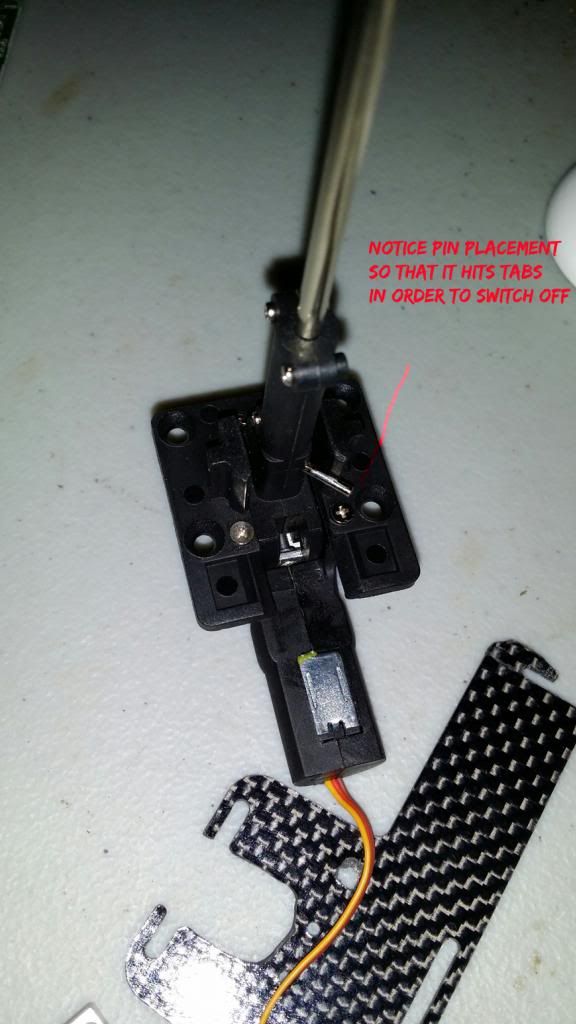

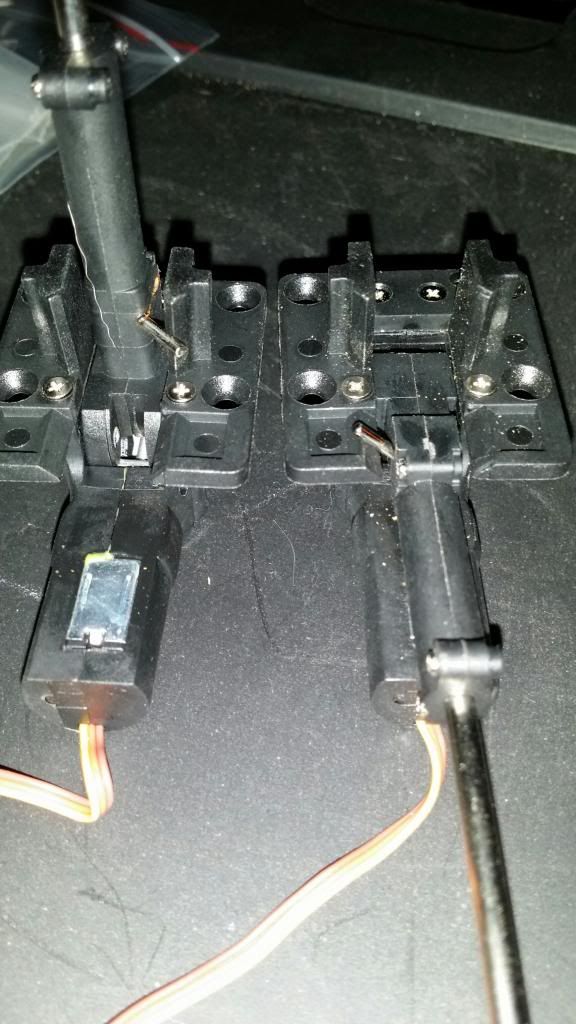

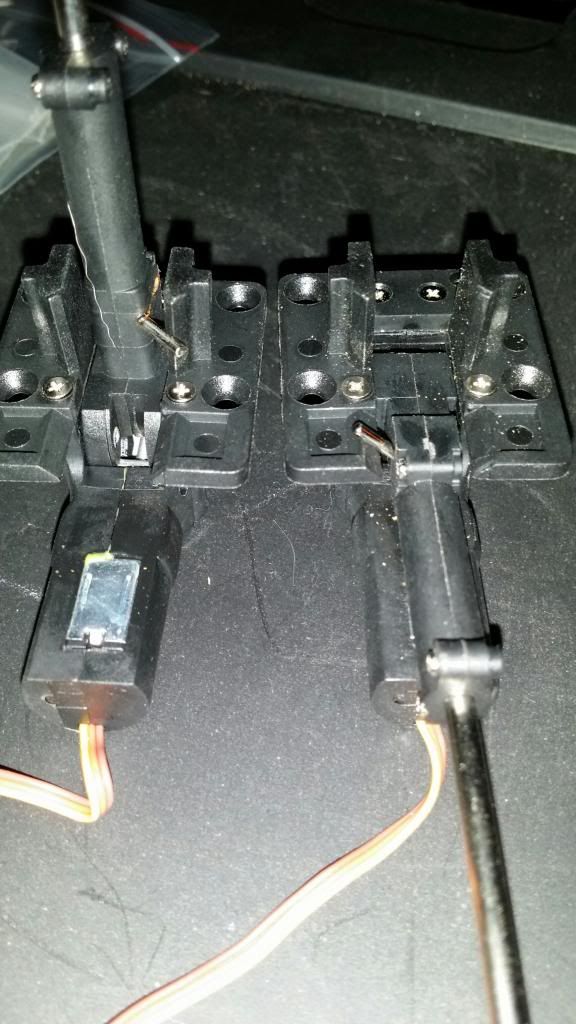

I too the leg ount portions, and then using a dremel to notch out for the gear to lower, I then took the trigger plate off the retract, used it as a template, and drilled the bolt holes- I used 2 of the intended holes on the plate for reinforcement bolts to tiny aluminum blocks with threads (M2x4) I then reused the screws to mount the plate back on as the 2 prongs are the trigger to stop these servoless motors (which shut off power draw after 10 seconds... feckin SWEET!)

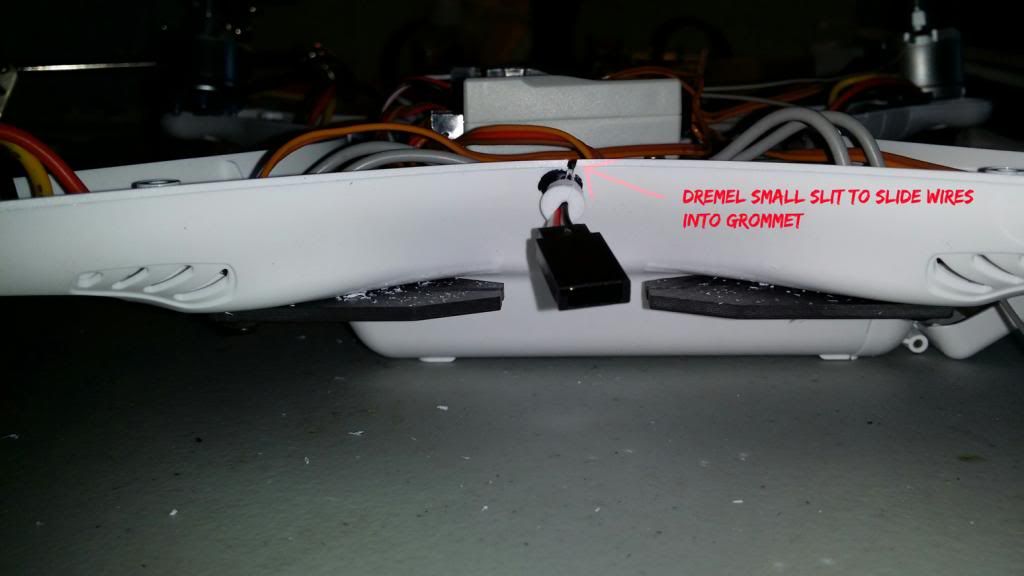

Notice the stock white grommets for the wires? They will route through the shell in the side exactly where the top and bottom meet- I will dremel a half circle notch top and bottom, and this will sandwich between the halves making a tight support on the wire and a clean look.

Here is a closeup of right before I decided where to place the bolts, or how to mount the landing gear assembly and plate to the slots which mount at the original landing gear location- I am using the mag glass as a jig to hold it while I contemplate- I think I will gorilla glue it as it does not need to be removed and that may save me a gram.

Once the t-motors get here (new 2.0 versions) and I get the guts all back in, I will see about posting up a killer video to make all you fixed leg Phantom pilots jelly.... neener-neener.

What is cooler than a well built and set up multi-rotor when it take off, hesitates for a sec, and then retracts it's landing gear up and out of the potential shot? For me, it is just wicked. (I know- small minds)

So I set out to see if it was possible, and actually feasible with the goal to not add too much weight to make it pointless... I think I pulled it off.. or up :roll:

Here are the 18 gram retracts found on ebay that are the foundation for the project: http://www.ebay.com/itm/121228846555

Be sure to add a y- cable as this will connect the gear into the Rx: http://www.ebay.com/itm/181180218953

You need to have an aftermarket radio and receiver- I use a Futaba and a FrSky TFR8SB (8 to 16 channels) with the landing gear hooked in on channel 8 and triggered by a single 2 way switch (H on my 10CAG) The Rx stated will bind to any FASST Futaba, and with standard config at your specs on the radio, you still do not loose X1 or the gimbal tilt. This is a whole other thread, so I will not go into detail on radio and receiver binding and programming- I am counting on you already understanding that part.

Next I liberated some parts from a set of CF landing gear that was removed due to too much weight- here is where the DIY in you will have to shine through- I would like to have dewey make a special mount, and then put it together but I doubt there would be enough demand- but based on what I have done here, he could make a few measurements and put something together rather easily if he, or someone else with a 3d printer was motivated. It would reduce the weight by half I believe from my mock up.

I too the leg ount portions, and then using a dremel to notch out for the gear to lower, I then took the trigger plate off the retract, used it as a template, and drilled the bolt holes- I used 2 of the intended holes on the plate for reinforcement bolts to tiny aluminum blocks with threads (M2x4) I then reused the screws to mount the plate back on as the 2 prongs are the trigger to stop these servoless motors (which shut off power draw after 10 seconds... feckin SWEET!)

Notice the stock white grommets for the wires? They will route through the shell in the side exactly where the top and bottom meet- I will dremel a half circle notch top and bottom, and this will sandwich between the halves making a tight support on the wire and a clean look.

Here is a closeup of right before I decided where to place the bolts, or how to mount the landing gear assembly and plate to the slots which mount at the original landing gear location- I am using the mag glass as a jig to hold it while I contemplate- I think I will gorilla glue it as it does not need to be removed and that may save me a gram.

Once the t-motors get here (new 2.0 versions) and I get the guts all back in, I will see about posting up a killer video to make all you fixed leg Phantom pilots jelly.... neener-neener.