I am going to share my hell over the past week. I purchased some black carbon fiber props. Flew them a couple times with no issues. Last weekend I flew up around 1500' to get a shot of a city (my landing site was a empty football field). after the shots, I brought the P3P back down and swapped out batteries.

I went to take back off and I was hoovering around 10 feet off the ground. I gave up command and forward command at the same time, that I have done 100's of times and when it spun up, one of the black CCW carbon fiber blades came off and flipped over and crashed on some concrete.

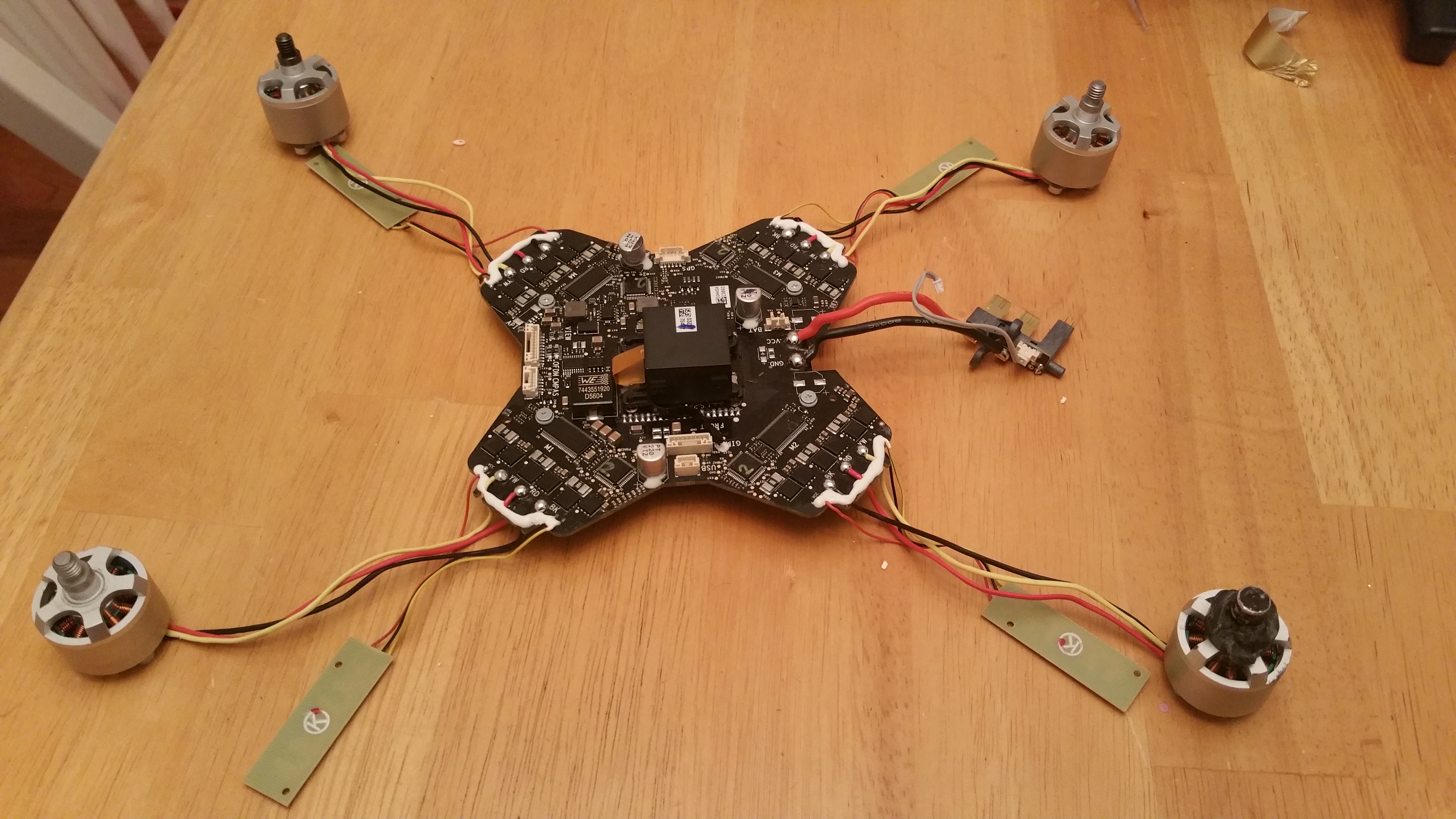

Upon inspection (see pictures attached) it got so hot it melted to the motor stem and even the plastic melted in to the threads. Needless to say a new motor was needed at the least. Due to not having OEM blades on the P3P, I had a feeling they would not cover the P3P under warranty.

So here is where I have been to hell and back. Upon inspection of my P3P, I needed to do and replaced the following:

1) New Shell (other one was pulled away and not usable. I would have replaced it anyways, too much scuff's)

2) Yaw are was bent (Camera came off on impact -- Replaced with Aircraft Grade Aluminum)

3) Anti-Vibration Mounting Plate (replaced with Carbon Fiber)

4) New Engine

I have got 12+ plus hours in taking the P3P COMPLETELY apart and putting it back together. I took every screw out, every wire, etc. I then went ahead and did the RC Antenna Mod to the RC since I was on a roll.

My advice:

1) Make your wife and children leave the house (I was repairing on the kitchen table) due to profanity coming from the dining room (honestly, I was not too bad).

2) Make a picture of each part and screw size goes where (lots of **** screws)

3) IF you have hair, when you are done you will need to join hair club for men.

4) Have the right tools, buy a $6 RC tool kit, you will need it (Amazon).

5) Wife's tweeters sure came in handy

6) Seen several spots on the wall where I through the P3P would look good thrown against (kept thinking you have 2K in this).

7) I think I need glasses

8) You get it back together and then realize you didn't have enough slack to plug cable back in to the main board (I walked around the house on that one a few times)

9) Do not drink while putting the P3P back together

10) It is a wonder I am still married [edited]

At the end of the day it was very tedious task moving everything to a new shell. I feel confident I can completely take a P3P apart and put it back together (technically with my errors, I got lots of practice). To those who show you how to take apart and put it back together on Youtube in a 5 minute video, FU..... LOL

Thanks for listening to my experience. My suggestion, do not use Carbon Fiber props.

www.wvdroneflyers.com -- My website (Thinking about starting a business, went ahead and started building the site). If anyone local (Charleston WV area) would like to fly or need help, just give me a shout.

[email protected] -- If I can be of any assistance!

I went to take back off and I was hoovering around 10 feet off the ground. I gave up command and forward command at the same time, that I have done 100's of times and when it spun up, one of the black CCW carbon fiber blades came off and flipped over and crashed on some concrete.

Upon inspection (see pictures attached) it got so hot it melted to the motor stem and even the plastic melted in to the threads. Needless to say a new motor was needed at the least. Due to not having OEM blades on the P3P, I had a feeling they would not cover the P3P under warranty.

So here is where I have been to hell and back. Upon inspection of my P3P, I needed to do and replaced the following:

1) New Shell (other one was pulled away and not usable. I would have replaced it anyways, too much scuff's)

2) Yaw are was bent (Camera came off on impact -- Replaced with Aircraft Grade Aluminum)

3) Anti-Vibration Mounting Plate (replaced with Carbon Fiber)

4) New Engine

I have got 12+ plus hours in taking the P3P COMPLETELY apart and putting it back together. I took every screw out, every wire, etc. I then went ahead and did the RC Antenna Mod to the RC since I was on a roll.

My advice:

1) Make your wife and children leave the house (I was repairing on the kitchen table) due to profanity coming from the dining room (honestly, I was not too bad).

2) Make a picture of each part and screw size goes where (lots of **** screws)

3) IF you have hair, when you are done you will need to join hair club for men.

4) Have the right tools, buy a $6 RC tool kit, you will need it (Amazon).

5) Wife's tweeters sure came in handy

6) Seen several spots on the wall where I through the P3P would look good thrown against (kept thinking you have 2K in this).

7) I think I need glasses

8) You get it back together and then realize you didn't have enough slack to plug cable back in to the main board (I walked around the house on that one a few times)

9) Do not drink while putting the P3P back together

10) It is a wonder I am still married [edited]

At the end of the day it was very tedious task moving everything to a new shell. I feel confident I can completely take a P3P apart and put it back together (technically with my errors, I got lots of practice). To those who show you how to take apart and put it back together on Youtube in a 5 minute video, FU..... LOL

Thanks for listening to my experience. My suggestion, do not use Carbon Fiber props.

www.wvdroneflyers.com -- My website (Thinking about starting a business, went ahead and started building the site). If anyone local (Charleston WV area) would like to fly or need help, just give me a shout.

[email protected] -- If I can be of any assistance!

Last edited by a moderator: