My gimbal started tilting to the left and I have never crashed it in fact not even a hard landing. Sometimes during the flight if I make a hard yaw move in either direction it will come very close to level but then slowly return to the position shown. Found several quick fixes with googlefu. I can take the back cover off and align the flat part of the shaft with the top of camera and it will be level after reassembly. I then apply the green loctite that is recommended and it will stay level for a couple flights but then do the same thing again. Any suggestions?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Gimbal Tilt problem

- Thread starter UgashikBob

- Start date

Hi Bob, please let us know if you are able to fix the problem. I am having the same issue. I haven't crashed at all nor have I had any hard landings. Everything on the gimbal looks fine except the camera is slanted. Took it to a dealer in Panama and they aren't able to figure it out. They updated the firmware/software/everything and recalibrated and nothing. They also took of the gimbal backplate to see if it had gotten loose from there and still nothing. They are out of ideas.

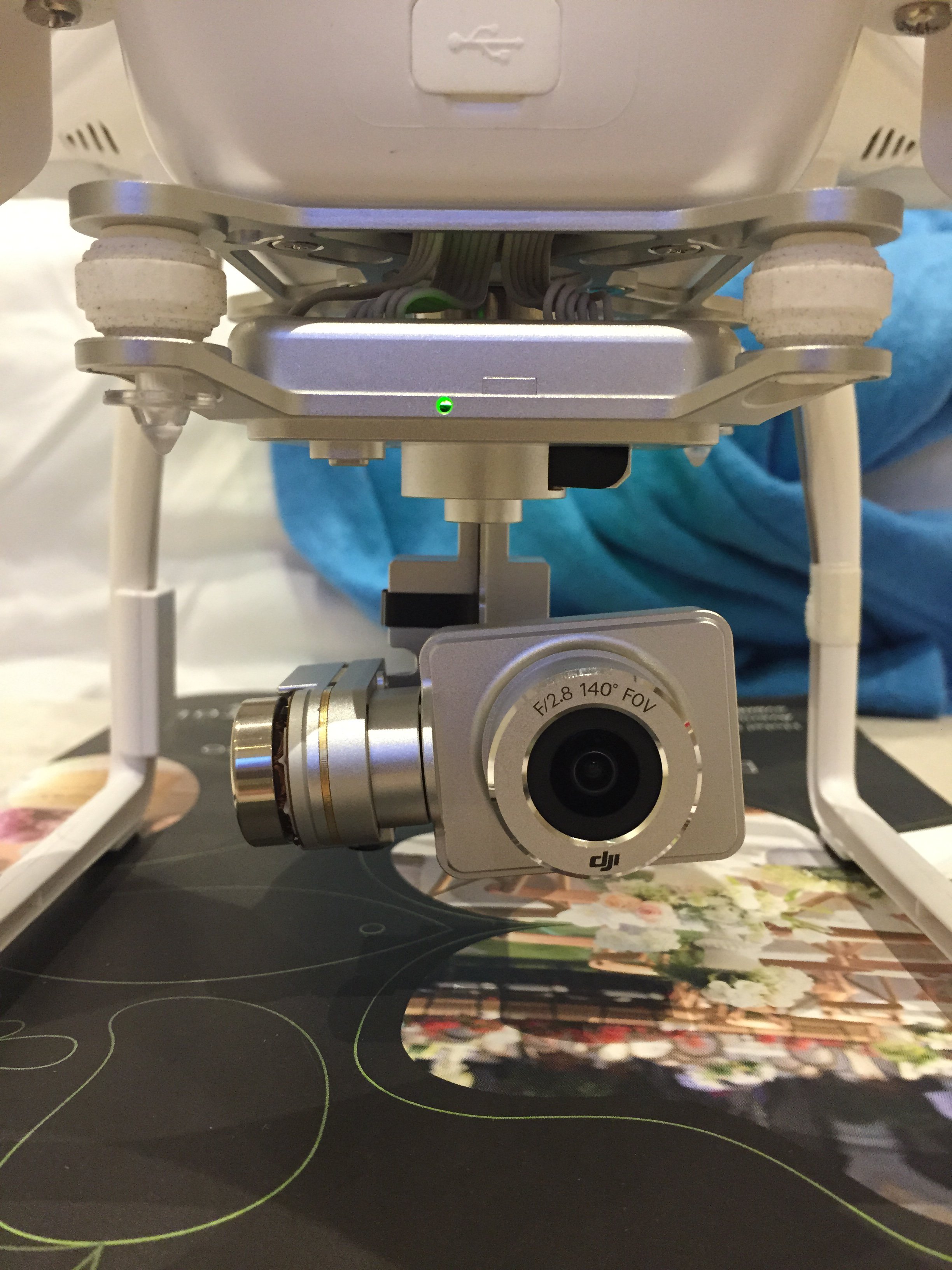

This is basically how my camera is leveling right now:

This is basically how my camera is leveling right now:

Attachments

saidnd:

Appears we have the same problem. There are several you tube videos to allegedly cure this problem but they have not worked for me. As mentioned before aligning the flat spot on the shaft with the top of the cam fixes it temporarily but doesn't explain why it rights itself after a yaw movement and then slowly slips out of alignment unless it is slipping on the shaft. Several posts have said this is a poor design with a press fit holding the shaft and easily broken with a crash or hard landing hence all the small repair facilities with major job security. I live in a very remote area and sending it anywhere is a long process.

Appears we have the same problem. There are several you tube videos to allegedly cure this problem but they have not worked for me. As mentioned before aligning the flat spot on the shaft with the top of the cam fixes it temporarily but doesn't explain why it rights itself after a yaw movement and then slowly slips out of alignment unless it is slipping on the shaft. Several posts have said this is a poor design with a press fit holding the shaft and easily broken with a crash or hard landing hence all the small repair facilities with major job security. I live in a very remote area and sending it anywhere is a long process.

Is the camera balanced with the power off?My gimbal started tilting to the left and I have never crashed it in fact not even a hard landing. Sometimes during the flight if I make a hard yaw move in either direction it will come very close to level but then slowly return to the position shown. Found several quick fixes with googlefu. I can take the back cover off and align the flat part of the shaft with the top of camera and it will be level after reassembly. I then apply the green loctite that is recommended and it will stay level for a couple flights but then do the same thing again. Any suggestions?

The new Phantom I got on March 16th was perfectly balanced but had a bad barometer. The replacement I received has a camera that tilts with the power off.

Adding two washers balances it. Does anyone know how unusual it is for cameras to be out of balance? Is there some defect that will affect picture quality or other effects I haven't noticed yet other than tilting with power off?

Anyway, the more balanced it is with the power off the less work the gimbal has to do to keep it level.

- Scott

Have you tried an advanced calibration, if not, ensure when you do, do it on a completely level surface. It fixed my gimbal problem

Scott848:

That is the first photo I have seen of a balanced gimbal with power off. Will balance and try it.

DownUnderPhoto

Have done many advanced calibrations but will double check surface for level.

burlbark;

Any video or specifics of how you disassemble and rough up the surface. Warranty is not the issue and considered red loctite but always thought that was a forever deal unless you heated it.

That is the first photo I have seen of a balanced gimbal with power off. Will balance and try it.

DownUnderPhoto

Have done many advanced calibrations but will double check surface for level.

burlbark;

Any video or specifics of how you disassemble and rough up the surface. Warranty is not the issue and considered red loctite but always thought that was a forever deal unless you heated it.

- Joined

- Oct 6, 2014

- Messages

- 502

- Reaction score

- 21

Scott848:

That is the first photo I have seen of a balanced gimbal with power off. Will balance and try it.

DownUnderPhoto

Have done many advanced calibrations but will double check surface for level.

burlbark;

Any video or specifics of how you disassemble and rough up the surface. Warranty is not the issue and considered red loctite but always thought that was a forever deal unless you heated it.

The roll shaft motor shaft is a press fit in the pitch motor assembly housing. If you remove the ribbon cable and the roll brushless motor controller, you can then grab the roll shaft from the controller side and twist and pull the 2 halves apart. Most of them I work on fall apart easily. When joining them if the gap is too great I use a brass bushing and hand fit it. I redloctite it in place using compression and twisting and it really grabs good. The amount of surface area to bond on the shaft is very small so there is no chance of it being unbreakable, even with the red. In fact I like them to break apart rather than transmit all energy to the j-arm and the main board. I roughen the mating surface of the shaft with a diamond file, it cuts nice deep grooves that really grab. I touch the aluminum up a little also, trying not to increase the hole size.

burlock:

The process I used (unsuccessfully) of removing the cover and aligning the shaft with top of the cam and the green locitte was fairly easy but concerned about going further in depth with my location making parts very difficult and time consuming to acquire. Will try and find a you tube showing the dis assembly you describe. Appreciate the input.

The process I used (unsuccessfully) of removing the cover and aligning the shaft with top of the cam and the green locitte was fairly easy but concerned about going further in depth with my location making parts very difficult and time consuming to acquire. Will try and find a you tube showing the dis assembly you describe. Appreciate the input.

Similar threads

- Replies

- 3

- Views

- 1K

- Replies

- 8

- Views

- 793

- Replies

- 4

- Views

- 2K