I was thinking (being in manufacturing myself) there could be a few reasons for the cracking problem on the P3.

- Flight fatigue and stress over time

- Off Balance motor due to rotor damage

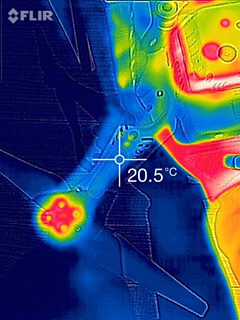

But look at this, a FLIR image of a P3 after about 1 minute of hovering

Heat buildup from the motor is NOT good for the plastic. Combine that with vibration and over a period of time you get brittle arms. I saw a number of 3d printed re-inforcing plates - this could in fact increase the heat issue What we actually need is machined aluminium plates, those will acted as a heatsink as well..

Any thoughts?

- Flight fatigue and stress over time

- Off Balance motor due to rotor damage

But look at this, a FLIR image of a P3 after about 1 minute of hovering

Heat buildup from the motor is NOT good for the plastic. Combine that with vibration and over a period of time you get brittle arms. I saw a number of 3d printed re-inforcing plates - this could in fact increase the heat issue What we actually need is machined aluminium plates, those will acted as a heatsink as well..

Any thoughts?