After replacing the camera/gimbal @ a cost of $679.00 + shipping, I figured I had to figure out a way to give it more protection and still not add more wind resistance. In this case I used cable lacing cord and duct table. :roll: (red neck engineering)

To start with I bought a bottom camera guard from "fastsmiles". It's carbon fiber and very strong. Its adds rigidy to the phantoms legs and protects the camera from the bottom. The back of the gimbal is protected by my LED high intensity lamp (with it on I always know the orientation of my bird. Just rotate until I see the light).

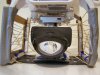

The right side is a hinged door (to get to the gimbal lock, and SD card) it is tied shut before flight.

As you can see, the lacing cord is run back and forth and locked into place with the duck tape.

Will all this work ?? Time will tell, but at least it's something.

From my experience with the gimbal, not too much will help if you have a hard landing, especially, with the bird upside down. The 2nd (Y axis) gimbal motor takes the full inertial weight of the camera and tilt gimbal. The shaft from the 2nd gimbal is only press fit into the mating part. At impact it can and does break free. First sign of damage is camera tilt. If the damage is not too bad, there are threads on this site, on how to repair it.

To start with I bought a bottom camera guard from "fastsmiles". It's carbon fiber and very strong. Its adds rigidy to the phantoms legs and protects the camera from the bottom. The back of the gimbal is protected by my LED high intensity lamp (with it on I always know the orientation of my bird. Just rotate until I see the light).

The right side is a hinged door (to get to the gimbal lock, and SD card) it is tied shut before flight.

As you can see, the lacing cord is run back and forth and locked into place with the duck tape.

Will all this work ?? Time will tell, but at least it's something.

From my experience with the gimbal, not too much will help if you have a hard landing, especially, with the bird upside down. The 2nd (Y axis) gimbal motor takes the full inertial weight of the camera and tilt gimbal. The shaft from the 2nd gimbal is only press fit into the mating part. At impact it can and does break free. First sign of damage is camera tilt. If the damage is not too bad, there are threads on this site, on how to repair it.