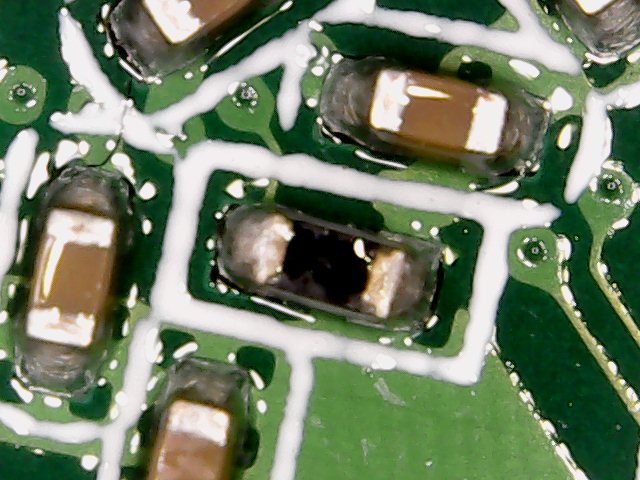

The pic shows some typical solder joints on my PV2+ onboard WIFI card. I suspect that the board has overheated which is apparently a common problem that drops the video to the mobile device. I get video feedback for about 60 seconds when the bird is powered up cold a

nd then it drops the video but still shows telemetry on the app.

nd then it drops the video but still shows telemetry on the app.

I notice that all the solder joints are a dull color as shown in the pic and wondering if that indicates bad connections. Shouldn't the solder be bright?

Also wondering where I can find the circuit diagram of this WM301_WIFI_2G_V1 circuit card that is one of the two cards in the wifi module. Is it possible to repair the board by reflowing the solder using a home oven?

I notice that all the solder joints are a dull color as shown in the pic and wondering if that indicates bad connections. Shouldn't the solder be bright?

Also wondering where I can find the circuit diagram of this WM301_WIFI_2G_V1 circuit card that is one of the two cards in the wifi module. Is it possible to repair the board by reflowing the solder using a home oven?